The lithium-ion batteries used in electric vehicles are being improved. Automobile manufacturers are working on more powerful lithium-ion batteries with longer ranges and faster charging times. Along with these advancements, improving safety is becoming increasingly important in the development of electric vehicles. Li-ion batteries emit a substantial amount of heat while in use and while charging, as we discussed in our previous blog post, 11 Considerations for Selecting Thermal Interface Materials for Electric Vehicle Li-Ion Batteries.

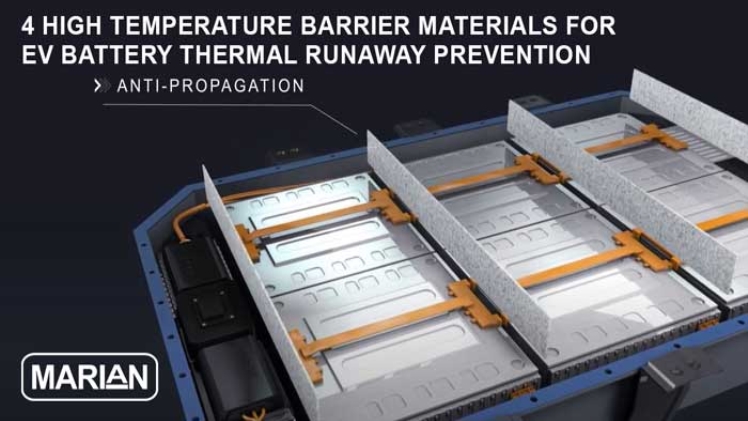

Placement of protective tailored flame retardant insulating materials between the components of the battery cell, module, and pack, in addition to the usage of thermal management materials, can provide extra thermal and electrical insulating protection. Due to space and weight limits, however, introducing such materials can be difficult. We’ll go through four materials that can improve the safety of lithium-ion batteries used in electric car charging points vehicles in this piece. To find more about EVB tape, please visit our website.

ITW Formex

For engineers and designers, Formex is a good choice. It has a high dielectric strength and is quite durable. It’s also flame retardant (UL94 V-0), which means it complies with all safety and environmental regulations.

To create a custom dynamic 3D shape, Formex can be die-cut, scored, and folded. Marian can also use PSA to laminate Formex materials for ease of use.

3M Flame Barrier Products

3M FRB Series Products are flame retardant (UL94 5VA) thin flexible insulation with high dielectric strength and strong arc and track resistance constructed of inorganic materials. These materials are ultra-thin (0.245 mm), light, and dimensionally stable. Marian is capable of using PSA to laminate 3M FRB materials. You can find more about Flooring systems here.

Kapton Polyimide Films

Polyimide films (also known as Kapton by DuPont) are commonly utilised in applications that undergo severe heat and vibration. Polyimide films are flame resistant (UL94 V-0), which means they can keep their electrical, chemical, and mechanical qualities even when exposed to extreme temperatures.

Mylar Polyester Film

Polyester films (also known as Mylar by DuPont) are used in a variety of applications that need electrical insulation, thermal resistance, and dimensional stability. PET sheets function as a dielectric insulator over a temperature range. Depending on the use within the battery, another of the products indicated above may be more suitable for greater temperatures.

Work with Marian

Marian works closely with ITW, 3M, tesa, and a number of other leading suppliers of tailored insulator materials. Your Marian sales engineer can offer the best materials for your application after learning about the thermal, electrical, and mechanical requirements. For testing, material samples and prototypes can be given immediately. Examine the material data sheets. Marian will choose the best manufacturing methods for creating unique die-cut components that are the right size and shape for the battery application. Marian is also acquainted about how the chosen materials will accept adhesive if it is required, as well as how the PSA will perform in the application’s conditions. Selective zone lamination, merging different materials, and adding assembly aids like pull tabs and extended liners are all possible with lamination.